Exhibitor Sneak Preview

The German Pavilion:

1 pavilion. 14 companies. Unlimited opportunity

Fourteen German companies showcase their innovations in the official German Pavilion at hy-fcell Canada 2a024!

The German Pavilion “made in Germany” provides a dynamic platform to foster connections with hydrogen industry leaders and offers extensive insights into Germany as a prime business location.

Hear from German companies and experts in the German Pavilion Forum on both days of the hy-fcell Canada expo.

Matthews International: Hydrogen technologies

When well-known companies join forces, expertise comes together and the symbiosis of different skills and experiences creates new perspectives.

Matthews | Saueressig | Olbrich | Polytype Converting

Our decades of experience in converting web materials gives us a depth and breadth of knowledge that creates unique conditions. Not only does it allow us to provide solutions for the hydrogen fuel cell market, but it also allows us to evolve from a global player in printing and converting to an innovation leader for the energy and automotive industries.

Our broad HFC portfolio ranges from graphite and metal bipolar plate (BPP) manufacturing equipment to catalyst coated membrane (CCM), gas diffusion layer (GDL) and gas diffusion electrode (GDE) production. We also offer our customers a wide range of customized rotary embossing and cutting cylinders.

We develop assembly or production lines according to our customers’ specifications.

Horváth & Partner: Developing Hydrogen Business Successfully

From strategy, advice, and planning to project implementation and management of the hydrogen business, Horváth & Partner Management Consulting provides professional support with a highly experienced team of consultants.

Our solution portfolio comprises:

- Strategy and overall solution design

- Development of technically and economically feasible H2 concepts

- Support with project development and implementation of hydrogen projects through to the commissioning

- Creation of new ecosystems through cross-industry networking

- Managing the business after commissioning

AVL Fuel Cell Canada: Stack Engineering & Testing

Founded in 2018 in Vancouver, AVL Fuel Cell Canada is the global center of excellence for PEM fuel cell stacks of AVL, one of the world’s leading mobility technology companies.

We work with leading OEMs targeting the development of new, or the improvement of existing PEM fuel cell & electrolyzer stack designs for a wide range of applications, including automotive, heavy duty, marine, and aviation. Our stack designs offer industry-leading performance and cost, and provide customers access to the best supplier technologies.

Our service portfolio includes:

Momentum Materials Solutions: Novel Carbon Material Unveiled

Discover our innovative mesoporous carbon materials, revolutionizing hydrogen fuel cells with superior durability.

Momentum Materials specializes in the development and manufacturing of nanoporous carbon materials as a catalyst support for hydrogen fuel cells and other energy applications, such as silicon anode batteries.

The NCP series products offer superior durability and high performance to proton exchange membrane fuel cell manufacturers, extending the fuel cell lifetime and reducing operational costs.

Join us in advancing towards a sustainable future!

ATEQ: A Revolutionary Leap in Leak Testing Technology

Leak testing plays a crucial role in the fuel cell industry, ensuring the integrity and safety of every component.

At ATEQ Canada, we specialize in providing advanced leak testing solutions tailored to the unique needs of the fuel cell sector. Our technology ensures that fuel cell systems are free from leaks, which is essential for maintaining performance, efficiency, and safety.

With our high-sensitive air pressure decay technology and helium mass spectrometry, we can detect even the smallest leaks, preventing potential failures and ensuring compliance with industry standards. Our flexible testing stations, equipped with removable tooling plates, allow for the seamless testing of various product types, catering to the diverse needs of fuel cell manufacturers.

Heraeus: Your strategic partner for precious metals

Strategic partner for precious metals within the hydrogen economy!

Visit the Heraeus Precious Metals booth to discover how precious metals are used at every step of the hydrogen value chain, including electrolysis, purification, transport, and fuel cells.

Heraeus Precious Metals supports scaling up the hydrogen economy through its innovative products, as well as by providing reliable supply of precious metals through trading and industrial recycling services.

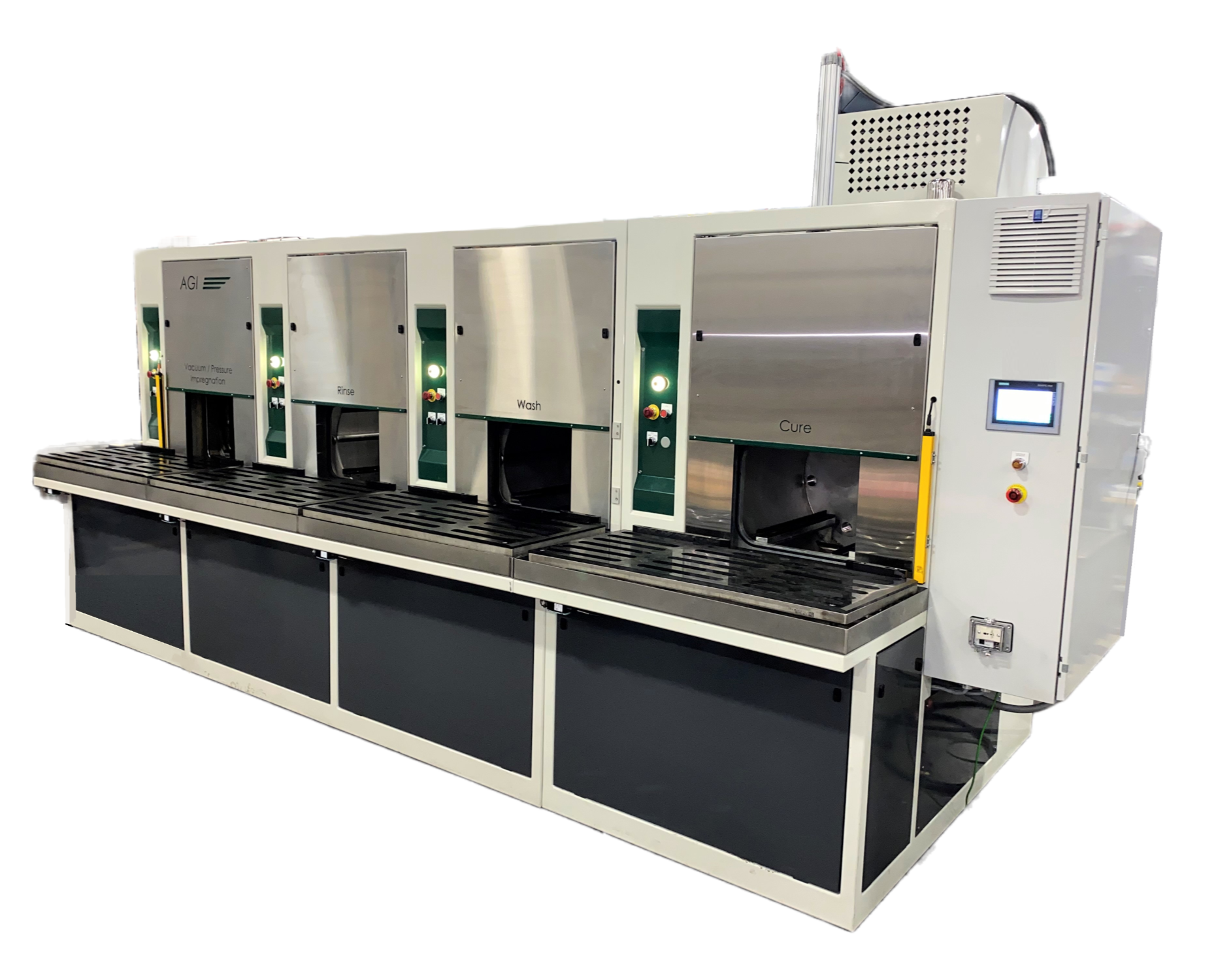

Godfrey & Wing brings a new spin on an old process

Fastest Resin Impreg Ever!

Godfrey & Wing has reimagined the process of resin impregnating flexible graphite plates.

What took hours, now takes seconds. And, with improved mechanical characteristics, no contamination, and no mess. And all this in a tiny footprint.

CellForm: Revolutionizing Hydrogen Tech

Revolutionizing hydrogen tech: CellForm’s groundbreaking bipolar plates boost efficiency, driving the shift to a cleaner, greener energy future.

In the quest for a sustainable energy future, hydrogen has emerged as a key player in decarbonization efforts across sectors like transportation and power generation. However, challenges persist in its cost and efficiency.

CellForm, a leading hydrogen technology company specializing in metallic bipolar plates, tackles these issues head-on. Their innovative manufacturing techniques produce finely detailed bipolar plates with enhanced performance and efficiency, vital for high-performance fuel cells and electrolyzers. By 2025, CellForm plans to produce 4.5 million plates annually, scaling up to 20 million by 2027.

This advancement not only boosts hydrogen’s competitiveness but also accelerates the shift towards sustainability. CellForm’s transformative approach heralds a new era in hydrogen technology, facilitating its broader adoption across diverse applications, including aviation.

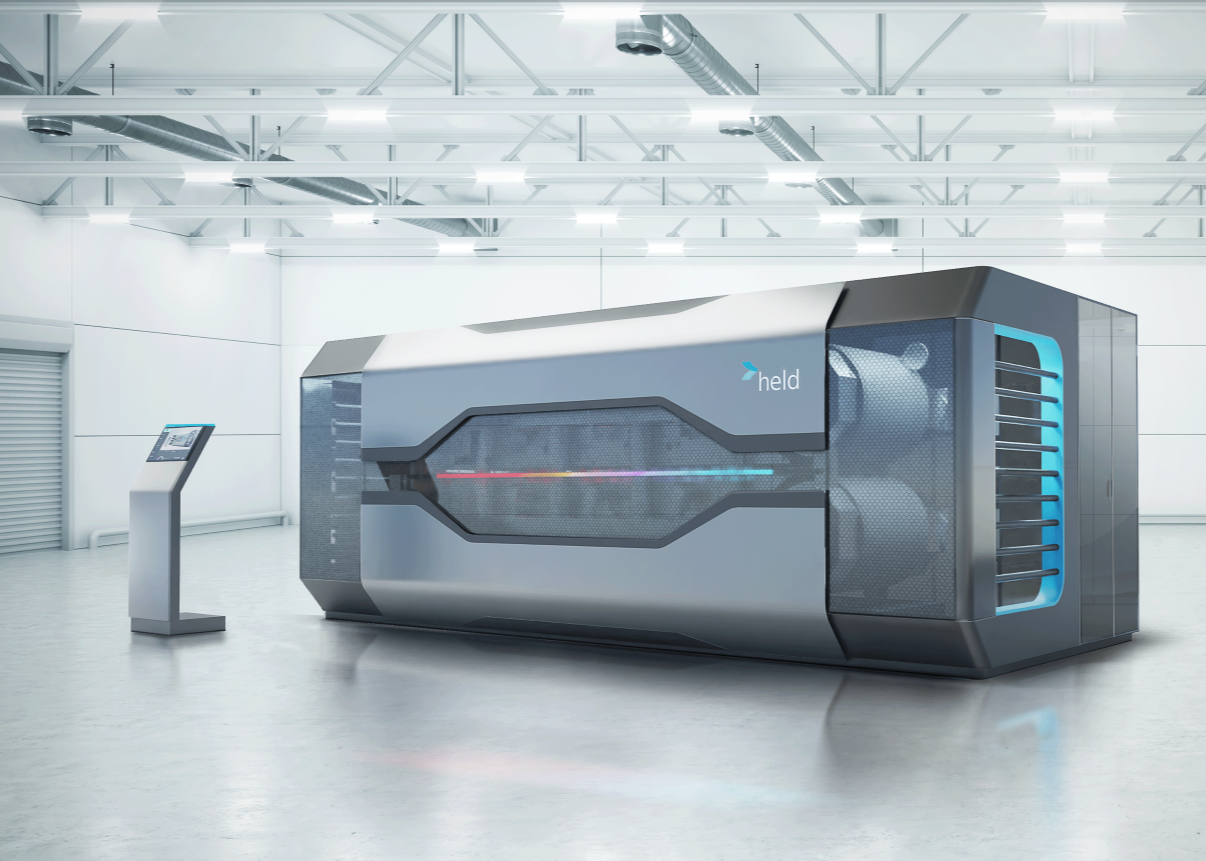

Held: New Generation Machine!

May we introduce? HAILEY – The first machine of our next-generation!

We embark on a new era of innovation at Held Technologie GmbH and present our new generation just in time for our anniversary.

- Intuitive new operating concept on large touchscreens

- Revolutionary belt change system allows more time for the essentials: Production of your materials

- Thinking far ahead: Automated functions to be part of the digital factory

- Significantly increased energy efficiency for a lower CO2 print and operating cost reduction

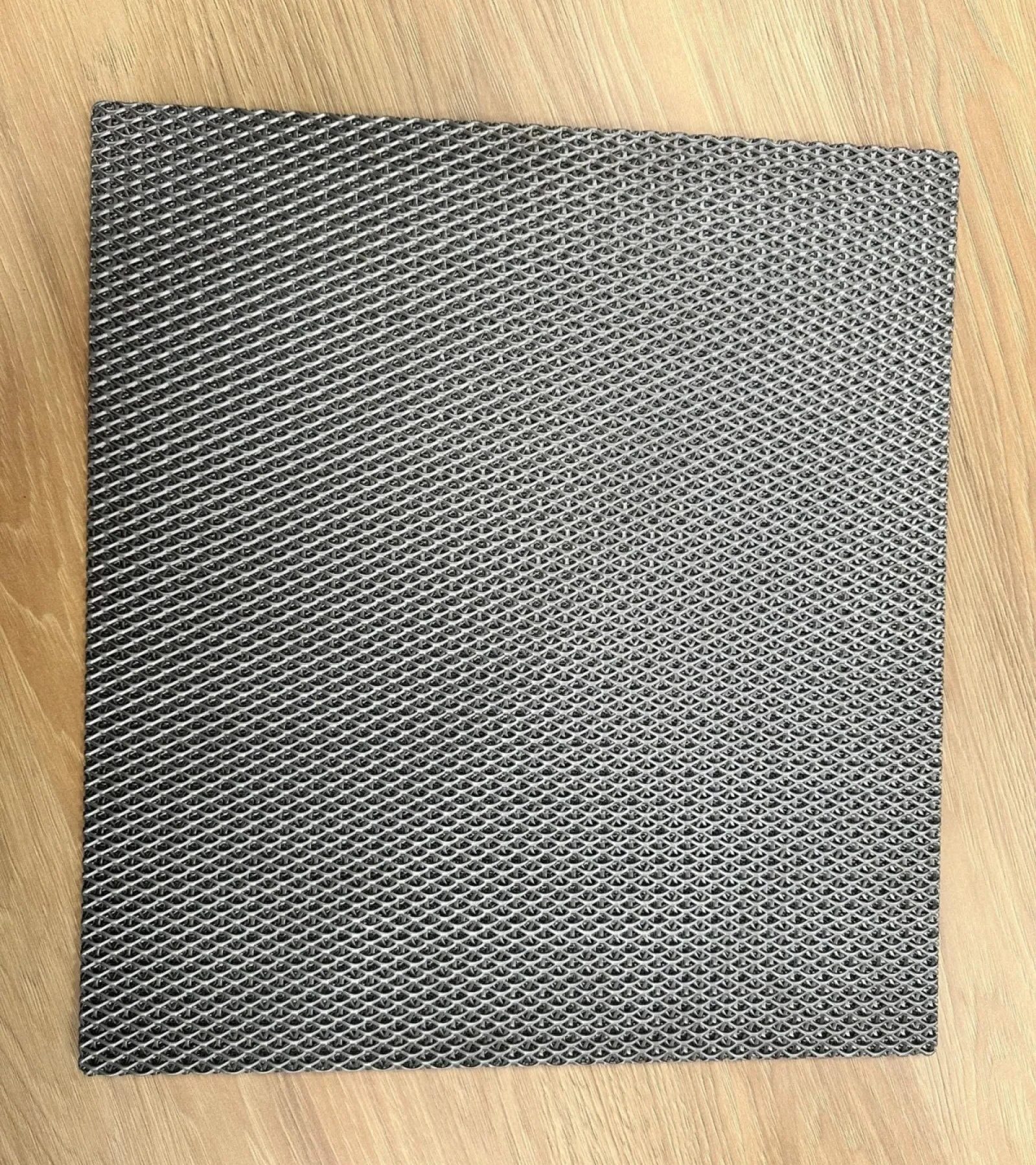

MeliCon: MeliDiff - gas diffusion layer

MeliDiff is a specially developed metallic expanded metal laminate for use in PEM electrolysis systems.

The purely metallic MeliDiff gas diffusion layers and the protonconducting membrane (PEM) are the main component of the PEM water electrolysis. The MeliDiff conducts electricity and water to the membrane and leads the forming gases H2 and O2 simultaneously. The MeliDiff gas diffusion layer are characterised by:

- High strength and minimal thickness tolerances which ensure a uniform surface pressure and electrical power distribution over the whole PEM area

- High porosity which ensures an excellent water supply and high water throughput for an optimal heat and gas dissipation

- A corrosion resistant material selection, titanium on the oxygen side and stainless steel on the hydrogen side

- Finest mesh size on the membrane side for the best membrane support and wide mesh size on the bipolar side for high water throughput for best heat transmission

- The option of welding the MeliDiff directly onto the bipolar plate significantly minimizes the electrical contact resistance

Graebener® Bipolar Plate Technologies:

Stack Press for Electrolyzers

Production technology to support technical testing of alkaline electrolyzer stacks

Our latest development is the stack press. It is used in the manufacturing process of electrolyzer stacks.

To be more precise, the stack press supports the technical testing of electrolysis stacks, which is necessary to confirm their full operability: The pre-assembled stack, which consists of a large number of plates, is first moved into the machine and then compressed to a defined height until a certain pressure is reached within the stack. This pressure must then be maintained unchanged for several hours. At this time, the stack is subjected to all the necessary technical tests carried out by the customer and with the help of further procedures. As soon as the tests are completed, the stack is finally assembled with tie rods or tension straps and the finished stack is removed.

The stack press for electrolyzers has a force of 800 tons and can handle stacks with a maximum height of approx. 3.0 m, a maximum diameter of 1.60 m and a weight of up to 12 tons per stack.

Greenlight Innovation: New Electrolyser Test Station

Greenlight is pleased to announce the release of a new, economical single cell electrolyser test station for R&D on either PEM or AEM chemistries: Introducing the E20 model.

Greenlight has been manufacturing electrolyser testing equipment since 1996, and can provide references from major companies and research institutes worldwide. We are a team of 300 people focused entirely on fuel cell and electrolyser testing equipment. Our electrolyser testing products range from 50W to 5MW.

the E20 test station can test electrolyser cells in the range of 50W to ~1KW. It is fully automated for unattended operation, featuring Greenlight’s Emerald control software. CE certificate of conformity is available and there are options for both PEM and AEM electrolysis.

SILO PSA: Hydrogen Purification System

SILO PSA is ideal for hydrogen production and biogas upgrading as well as CO2 capture and helium recovery. Custom inquiries welcome!

SILO PSA features an extremely small footprint and also available in a low profile version suitable for containerized equipment applications.

SILO PSA technology combines a proprietary single rotary distributor to eliminate over 50 process valves associated with comparable conventional PSA equipment and an integrated flow design to replace over 30 pipe spools with flow channels built into the distributor assembly. The result is lower CapEx, greater reliability, and an extremely compact system.

With over 45 years’ experience in pressure swing adsorption and rotary PSA design, manufacturing, sales, and support, the SILO team has optimized SILO PSA for price, performance, and RAS (reliability, availability, serviceability).

CIMtech: Powering The Future - Plug & Play H2 Portable Generators

Electrolyzer & Fuel Cell Manufacturing – Components & Assemblies. CIMtech Green Energy is instrumental in putting 60,000+ fuel cell devices in real world applications.

CIMtech-manufactured fuel cell components are utilized by global players such as Walmart, Amazon, and Home Depot for their hydrogen-powered forklift equipment & hydrogen fuel-cell powered electric vehicles such as HYVIA delivery vans in Europe (Renault Group), FedEx airport tuggers at Albany International Airport & hydrogen-fuel cell electric vehicles.

Two decades of manufacturing & development experience in fuel cell sector. CIMtech Green Energy DFM program has saved 5 million dollars to our customers. Our low volume injection molding processes can help your organization to launch products with lowest cost of manufacturing.

Powertech’s Advanced Mobile Refueler

Supporting the advancement of clean transportation technology through testing and development.

The Powertech’s mobile refueler supports a flexible, modular hydrogen system that scales easily with your needs (from a few vehicles to hundreds), without the required time and investment of permanent infrastructure. Whether you are readying your first hydrogen refueling solution or expanding existing systems, this mobile refueler is the most efficient, reliable, and cost-effective solution available.